Balancing a centrifuge requires that all tubes in the load: is a crucial aspect of laboratory operations, ensuring the safety and accuracy of experimental outcomes. An unbalanced centrifuge can lead to catastrophic consequences, ranging from equipment damage to potential hazards for personnel.

This comprehensive guide delves into the significance of centrifuge balance, exploring the factors that influence it and presenting practical methods for achieving optimal balance. By understanding the principles and techniques Artikeld herein, laboratory professionals can effectively mitigate risks and ensure the smooth operation of their centrifuges.

Importance of Balancing a Centrifuge

Balancing a centrifuge is crucial to ensure the safe and efficient operation of the equipment. An unbalanced centrifuge can lead to severe consequences, including:

- Excessive vibrations:Unbalanced loads can cause the centrifuge to vibrate excessively, which can damage the machine and the samples.

- Rotor failure:Severe vibrations can cause the rotor to fail, which can be catastrophic and pose a safety hazard.

- Sample damage:Unbalanced loads can result in uneven centrifugation, which can damage or destroy the samples.

It is essential to take safety precautions when operating a centrifuge, including:

- Proper training:All personnel operating a centrifuge must be properly trained and familiar with the equipment.

- Regular maintenance:Centrifuges should be regularly inspected and maintained to ensure optimal performance and prevent imbalances.

- Emergency procedures:Emergency procedures should be established and communicated to all personnel in case of an unbalanced centrifuge.

Factors Affecting Centrifuge Balance

Several factors can affect the balance of a centrifuge, including:

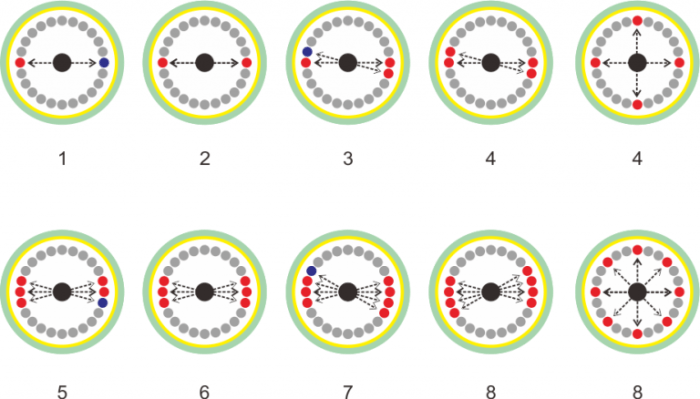

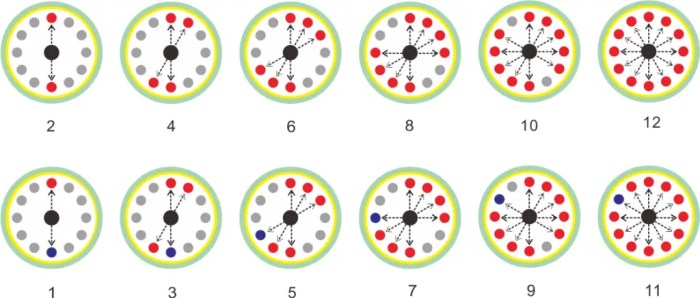

- Weight and distribution of tubes:The weight and distribution of the tubes in the rotor are the primary factors affecting balance.

- Rotor design:The design of the rotor can also impact balance. Rotors with symmetrical designs are generally more balanced than those with asymmetrical designs.

- Sample density:The density of the sample can also affect balance. Samples with higher densities tend to settle to the bottom of the tube, which can create an imbalance.

Methods for Balancing a Centrifuge

There are several methods used to balance a centrifuge, including:

- Manual balancing:This method involves manually adjusting the weight of the tubes in the rotor until the centrifuge is balanced.

- Automatic balancing:Some centrifuges have automatic balancing systems that adjust the weight of the tubes automatically.

- Tube adapters:Tube adapters can be used to equalize the weight of the tubes in the rotor.

Each method has its advantages and disadvantages. Manual balancing is the most accurate method, but it can be time-consuming. Automatic balancing is less accurate but faster and more convenient. Tube adapters are a simple and inexpensive way to balance a centrifuge, but they may not be suitable for all applications.

Troubleshooting Centrifuge Imbalance

If a centrifuge becomes unbalanced during operation, it is important to take the following steps:

- Stop the centrifuge immediately:Continuing to operate an unbalanced centrifuge can be dangerous.

- Identify the source of the imbalance:Check the weight and distribution of the tubes in the rotor.

- Rebalance the centrifuge:Use the appropriate balancing method to rebalance the centrifuge.

- Contact the manufacturer:If the centrifuge cannot be rebalanced, contact the manufacturer for assistance.

Regular maintenance and calibration of the centrifuge can help prevent imbalances. It is important to follow the manufacturer’s instructions for maintenance and calibration.

FAQ Overview: Balancing A Centrifuge Requires That All Tubes In The Load:

What are the consequences of an unbalanced centrifuge?

An unbalanced centrifuge can cause excessive vibration, noise, and heat generation, potentially damaging the equipment and its components. It can also lead to inaccurate experimental results due to uneven distribution of centrifugal force.

How can I identify an unbalanced centrifuge?

Signs of an unbalanced centrifuge include excessive vibration, unusual noises, and difficulty in reaching the desired speed. Additionally, the centrifuge may stop prematurely or display error messages.

What steps should I take if my centrifuge becomes unbalanced during operation?

If a centrifuge becomes unbalanced during operation, it should be stopped immediately. The load should be carefully removed and rebalanced before resuming operation.